FK 45 FOODGRADE – 2-component high-solid epoxy resin coating, certified according to VO (EU) 1935/2004, VO (EU) 10/2011 for direct contact with food

Intended use

FK 45 FOODGRADE is a 2-component coating based on epoxy resin for interior surfaces in direct contact with food. FK 45 FOODGRADE is certified according to VO (EU) 1935/2004, VO (EU) 10/2011, for direct contact with food. The 2-component coating seals the surface and is characterised by very good substrate adhesion and high chemical and cleaning resistance.

The 2-component epoxy resin coating is particularly recommended for ceilings, walls, machines, tanks, containers, silos and other surfaces in the food-producing industry and agriculture. The GREEN-BLUE-BIO.FILM.STOP-Technology protects the surface of FK 45 FOODGRADE from virus and bacteria infestation.

Material base

- 2-component high-solid epoxy resin coating, solvent-based

Product features / properties

- Certified for direct contact with all foods (Tested simulants = A, B, C and D2)

- Surface protection virus and bacteria infestation by tested GREEN-BIO.FILM.STOP-Technology (ISO 21702:2019-05, ISO 22196:2011-08)

- Recommended by the Federal Association of Food Inspectors Germany e.V.

- High abrasion resistance: UNE EN ISO 5470-1-1999

- CE marking. Tested according to UNE-EN 1504-2:2005

- Waterproof

- No water absorption

- Disinfectant resistant (TÜV Rheinland tested)

- Low odour

- Colour: White, grey, transparent. For further colors, see technical data sheet

- Sealing

- Gloss level: Glossy

Areas of application

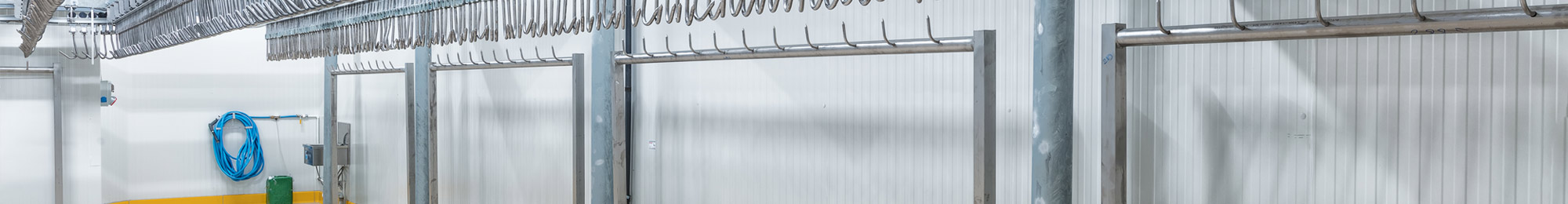

FK 45 FOODGRADE is particularly recommended as a heavy-duty, antibacterial ceiling and wall coating in production and cold rooms in the food industry. FK 45 FOODGRADE is also ideally suited as a renovation coating for metal panels/sandwich panels which show damage due to daily cleaning as well as chemical and mechanical loads.

Other recommended applications are interior coatings of tanks and silos in which food and feed are stored. Also, the coating of machines/boilers in which food is

produced. To be noted: Minimum dry film thickness for coating tanks and silos = 400µ.

When using strongly acidic/alkaline cleaning agents or filling materials, we recommend consulting our application technology department. The aim is to check whether FK 45 FOODGRADE has the optimum properties for the intended use. A possible alternative could then also be FK 100 FOODGRADE. With the double certification according to VO (EU) 10/2011 and FDA 21 CFR 175.300, FK 100 FOODGRADE is a variant with maximum chemical resistance, especially in the field of tank and silo coatings (see product information FK 100 FOODGRADE).

Processing

- Processing from + 12°C

- Brush, roller or airless spray application

- Drying time between coats >12h and <48h, cured after >14 days (20°C/ 60% rel. humidity)

- Dilution with FAKOLITH FK 45 THINNER

- Consumption: Approx. 300-600 g/m² (depending on the

intended use)

Container sizes

- 2,5 kg

- 7,5 kg

Downloads for the product

Ordering, price information and delivery

You would like to order our products, need an offer or do you have questions about ordering? Our sales department will be happy to assist you personally by telephone or e-mail.

FAKOLITH Farben / Sales

Phone: +49 (0)6253 / 23 94 - 23

Email: sales@fakolith.de

Information and service

We know the requirements for surfaces in food processing companies and supply functional coating solutions. Do you only have a short time window for the renovation? Do you have questions about the product selection, preparation or use of our FAKOLITH products? Our technical support is at your disposal personally by telephone or e-mail.

FAKOLITH Farben / Technical support

Phone: +49 (0)6253 / 23 94 - 18

Email: technical-support@fakolith.de